Categories

Locations

Shanghai,China - Global HQ

WH/DG,China - Mfg&Sales

Frankfurt am Main,Germany

EV e-Axle Motor and Inrunner BLDC

e-Axle motor, Robot arm

Inner roter BLDC Motor

The high performance inner rotor series feature high quality

This motor has an inner rotor structure with the coil fixed to the outside and stator with magnet rotating in the center. As it is easy to contol the rotation speed, BLIM is ideal for applications requiring fast response such as paper feeders for printer, ATMs and home appliances. Employing a strong magnet makes it possible to achieve high efficiency operation within a small package. Demand for energy saving components is increasing across all industries. Our engineering team can help design custom options to meet our customer's performance requirements.

Features:

Highest power density

Ball bearing standard

Driver electronics available

Low moment of Inertia

Superior heat dissipation properties

Standard Ingress Protection IP20

Frameless kits available

Brushless Inner Rotor DC Motor

Brushless motor 1632

Motor diameter: 16mm

Brushless motor 2419 2430

Motor diameter: 24mm

Brushless motor 2838 2852

Motor diameter: 28mm

Brushless motor 3625 3630

Motor diameter: 36mm

Brushless motor 3660

Motor diameter: 36mm

Brushless motor 4280

Motor diameter: 42mm

Brushless gearmotor 4258

Motor diameter: 42mm

Brushless gearmotor 4266

Motor diameter: 42mm

BLDC DC Servo 40

Motor diameter: 40mm

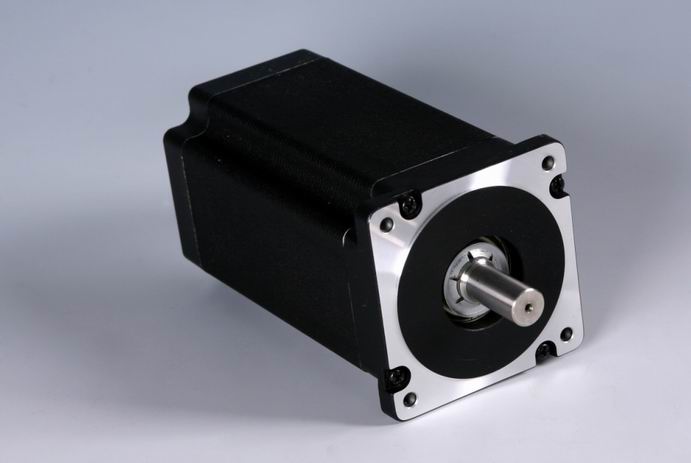

BLDC DC Servo 42

Motor diameter: 42mm

BLDC DC Servo 57

Motor diameter: 57mm

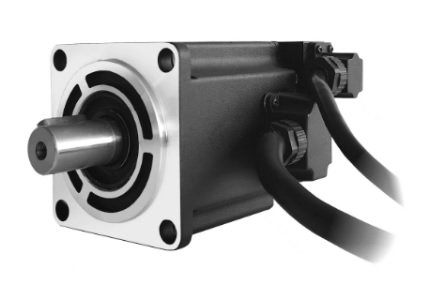

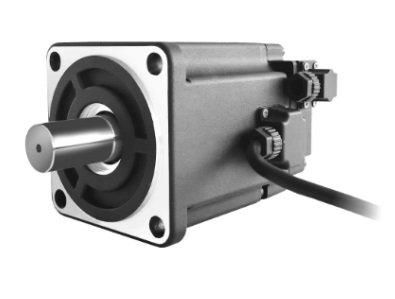

BLDC DC Servo 60

Motor diameter: 60mm

BLDC AC Servo 60

Motor diameter: 60mm

BLDC DC Servo 80

Motor diameter: 80mm

BLDC AC Servo 80

Motor diameter: 80mm

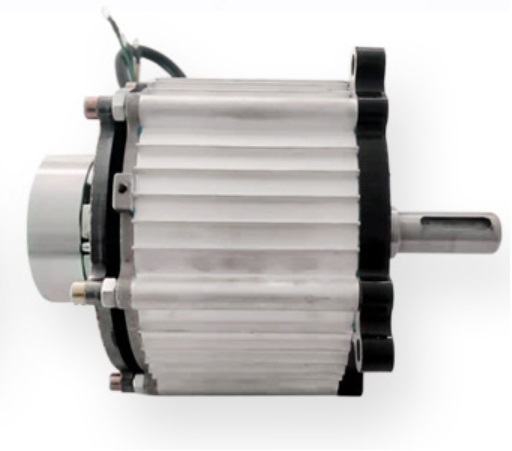

Electric axle brushless motors

350W-1.8kW eAxle motor

Motor diameter: 147mm

500W-1.2kW eAxle motor

Motor diameter: 140mm

500W-1.2kW eAxle motor

Motor diameter: 140mm

500W-1.2kW motor EM brake

Motor diameter: 140mm

2.5kW-4kW eAxle motor

Motor diameter: 140mm

2.5kW-4kW eAxle motor

Motor diameter: 140mm

2.5kW-4kW motor EM brake

Motor diameter: 140mm

3kW-4kW EV motor

Motor diameter: 159mm

5kW EV motor

Motor diameter: 159mm

5kW-7.5kW EV motor

Motor diameter: 175mm

10kW EV motor

Motor diameter: 192mm

12kW-18kW motor

Motor diameter: 192mm

Market solutions that use our motors

Improve efficiency and battery life in products like Vacuum cleaners, Electric bicycles,Wearable devices, Scanners, Massagers, Toy robot ,Drones and Minimal vibration.

Motor solutions

Enhancing EV performance and range, exemplified by electric drive axle and motor transaxle solutions for Off-road vehicles,Unmanned vehicles,Retrieval machines, Driverless transport systems and Intelligent logistics robots.

Motor solutions

Home automated robotic arm or The lawn mower robot in our garden, Motorized blinds, Curtains, Washing Machines, Dishwashers, Refrigerators, HVAC systems for tasks like agitating, rotating and controlling airflow and Smart locks.

Motor solutions

Industry 4.0, IoT, and AI require complex mechatronic systems. Uniqualis motor enhance productivity in Robotics, Conveyor systems, Pumps, Mixers and Lift actuator CCTV system or a Locking system.

Motor solutions

Brushless Motor Guide

Characteristics and Classification of Brushless DC Motors

The brushless DC motor "rotates its magnet". The rotor, made of a magnet, is rotated by magnetic fields that are generated by the current flowing through the stator windings. The current is switched by the sensor and electronic circuit.

Outer rotor type (the rotor is outside the stator)

Advantages

Easy to obtain large torque.

Speed is stable during constant rotation.

Disadvantages

The rotor is large (the motion is slow).

The outside rotor requires appropriate safety measures.

Inner rotor type (the rotor is inside the stator)

Advantages

Advantages

The rotor is small and can respond quickly.

The coil is located on the outside and the level of heat dissipation is high.

Disadvantages

Difficult to obtain large torque.

Magnets can be damaged by centrifugal force.